Philip Taylor built his insect refinery in the low foothills of Boulder County. Chickens from Black Cat Farm peck the dusty ground around the arched greenhouse. It's just about as far from the ocean as you could get.

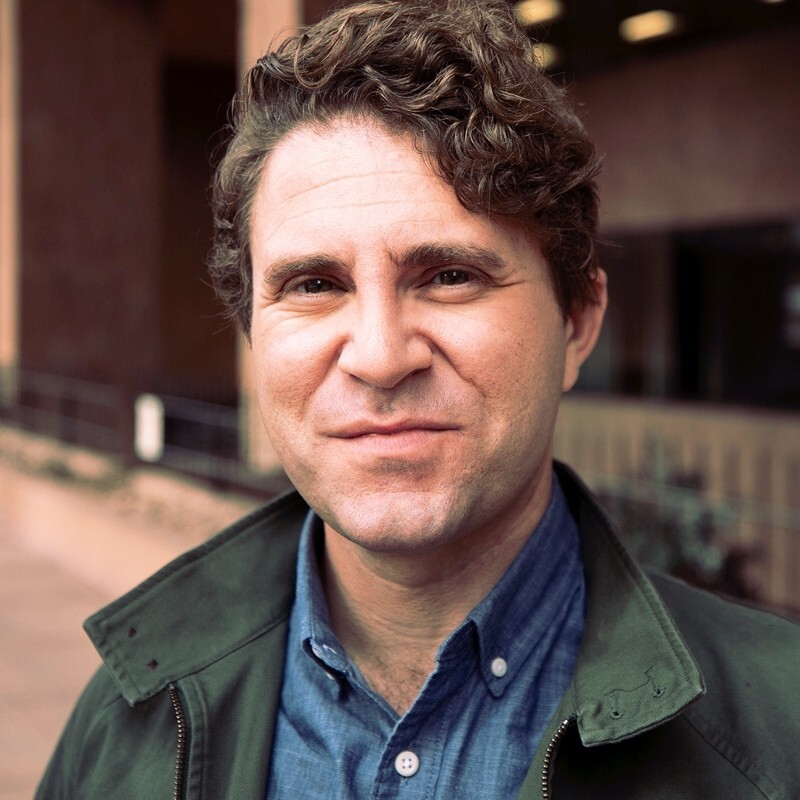

And yet, Taylor, an ecology researcher at the University of Colorado and the founder of Mad Agriculture, thinks the larvae growing inside could save marine ecosystems.

The 34-year-old Taylor also has a knack for branding. Posted just inside the greenhouse is a sign that reads, "The Ocean Is In Our Veins."

"I used to write that on the back of my Volvo when I was surfing the East Coast," he said. "The ocean is in our veins, man!"

Taylor means this literally. The protein in commercial animal feed often comes from meal and oil made from ground up fish from the ocean. So when people eat farmed chicken, pork or salmon, they're only one dietary degree removed from the sea.

"When we walk around and you feel your muscles tighten and your blood pumping, that's literally the protein from the ocean," he said.

Fish meal comes from small forage fish, like herring or sardines. Those species are a critical source of food for a wide range of marine life, never mind people. Demand has pushed stocks close to collapse. In 2016, the U.S. banned sardine fishing along the West Coast for the second straight year after finding populations had declined 90 percent since 2007.

That's why Taylor, a Maryland native, wears a trucker hat printed with a blueback herring. Every year, he returns to the Chesapeake Bay to search for the once-abundant fish. Every year, he can't find it.

"My effort is to restore those ecosystems by putting proteins on the market that don't destroy ecosystems," he explained.

In recent decades, scientists have managed to cajole soy into an imperfect replacement for fish meal. Still, the protein-rich beans come with their own set of problems. Soy production has led to widespread deforestation across the globe. Moreover, the whole project doesn't make sense to Taylor. He notes that fish and chicken evolved eating bugs, not genetically modified commodity crops.

That's why protein he is betting on are dried maggots fattened on Boulder's food waste.

Bug Farming

Inside Taylor’s Mad Agriculture greenhouse you’ll find a few plastic barrels stuffed to the brim with pressed ginger from Wonder Press, a Boulder juice company. It smells salty-sweet within the greenhouse because Taylor pickles the waste to preserve it.

Next, he loads the waste into trays and tosses in a small packet of cardboard. Each packet contains about 900 eggs of the black soldier fly, a species common to the world's tropical and subtropical forests. Once they're near food, the eggs hatch into maggots that explode their cardboard casings. The larvae are voracious. In about two weeks, they gorge themselves from eggs into dark squirmers that are about the size of a paper clip. Taylor grabbed a handful of nearly mature maggots from one tray.

"They're warm," he said. "You can feel their metabolism."

The next stop for the bugs is a hot oven. Taylor dries the maggots into flattened chips that can be ground and added to animal feed. He proudly claims that the final product is 42 percent protein and 34 percent fat--numbers that make his bugs comparable to fish meal.

A few lucky maggots from each batch get the chance to become adult flies in the greenhouse breeding area. This is where Taylor's training as a rainforest ecologist came in handy. He experimented with different light bulbs to reproduce the spectrum of light that filters down from forest canopies. Why? "They need to see each other's wing patterns in order to get it on," he explained. The work was submitted to the Journal of Insects for Food and Feed and is currently under review.

Taylor built the greenhouse to learn how to produce black soldier flies on a commercial scale. Right now, it can process about 500 pounds of food waste per month. His grand hope for Mad Agriculture is a facility that could get through 15 tons of waste per day.

Waste Not

Mark Burkeley, the CEO at Wonder Press, said that Taylor has helped his company meet their goal of zero landfill waste.

"His bugs are non-discriminatory," he said. "He's able to come through and does a clean sweep of whatever's left of our food waste."

Wonder Press has long recycled its waste on a voluntary basis. Now, all other business in Boulder will have to follow suit, since the city approved its Universal Zero Waste Ordinance. The idea is to help the city recycle or compost 85 percent of its waste by 2025. In 2015, only 28 percent the city's waste went toward generating new material. As of September 2016, all businesses in the city -- including restaurants and grocery stores -- had to facilitate the collection of compostables like food waste.

Eco-Cycle, a nonprofit waste service partner with Boulder Country, is one of the organizations helping businesses meet the new requirements. Right now, it hauls food waste about 60 miles to the A1 Organics compost facility in Weld County.

Dan Matsch, a manager at Eco-Cycle, thinks Taylor's bug system could provide an urban alternative for food waste. "My goal is to make compost cheap enough so everyone can use it," said Matsch. "And the key to that is keeping it local." So in theory, an urban fly refinery in Boulder could provide a cheaper destination for food waste and create valuable animal feed.

But Matsch noted barriers to Taylor's vision.

Federal regulations do not currently allow insects to be used in commercial poultry and aquaculture. Taylor said he has spoken to state regulators about overriding those rules, which a few states have already done. Also, the Food and Drug Administration is currently conducting trials with Ohio company EnviroFlight, which also plans to sell black soldier fly larvae as animal feed. A company spokesperson predicted that national approval could come sometime in 2016.

Bugs As Business

Another hurdle is money. Taylor estimates the cost of his facility would cost between $650,000 and $825,000, depending on whether he gets support from Eco-Cycle and free land from another partner.

"I'm not sure of the best model to do it, whether it's a nonprofit model or a business model," said Taylor.

Other companies have managed to make black soldier flies into compelling vehicles for profit. Enterra Feed of Vancouver, Canada built a largely automated fly refinery that can process 100 tons of food waste per day. The company is exploring a possible expansion to Seattle, Toronto and San Francisco. Ohio insect startup EnviroFlight was purchased by Intrexon, a corporate giant in the world of synthetic biology.

Taylor is also exploring whether Mad Agriculture could work as a for-profit startup. He’s had a pitch session with potential investors from Slow Money, a Boulder-based group that funds local food projects across the country. Woody Tasch, the group’s founder, said Taylor's plan fits squarely into his concept of nurture capital. Rather than promising a quick monetary return, Taylor's bugs could bring long-term ecological and social benefits to the Boulder community.

But could Mad Agriculture also turn a profit?

"Who the hell knows?" Tasch responded. "It's a very early stage thing. The people who put the capital in are going to have to people who are willing to accept the risk that there's a lot of business elements of this that have to be figured out over time."

So for now, Taylor is starting small. He plans to start a feeding trial in collaboration with a local chicken farmer. If it works, he'll start selling his dried maggots as a high-end treat for backyard chickens this month. The plan is a short-term way around the federal regulations. Pet chickens can eat maggots just like pet lizards can eat crickets.

Taylor sees it as a first step toward a kind of commerce that feeds into rather than off of the natural world. That's left him free to imagine success within the marketplace.

"My overarching vision is to really become the Patagonia of animal feed."