Last week, a crowd of more than 300 people gathered in a Greeley field to watch construction begin on what will be the largest Habitat for Humanity project in Colorado.

What they saw was a robotic arm squirting thin layers of concrete, one after another.

The grand opening of the Hope Springs community on Thursday marks the latest step in a multi-pronged attempt from 3D concrete printing company Alquist 3D to make Weld County a national hub for the nascent homebuilding technology. The company’s process replaces traditional methods of using bricks or lumber to frame the walls of a house with layer upon layer of specialized concrete.

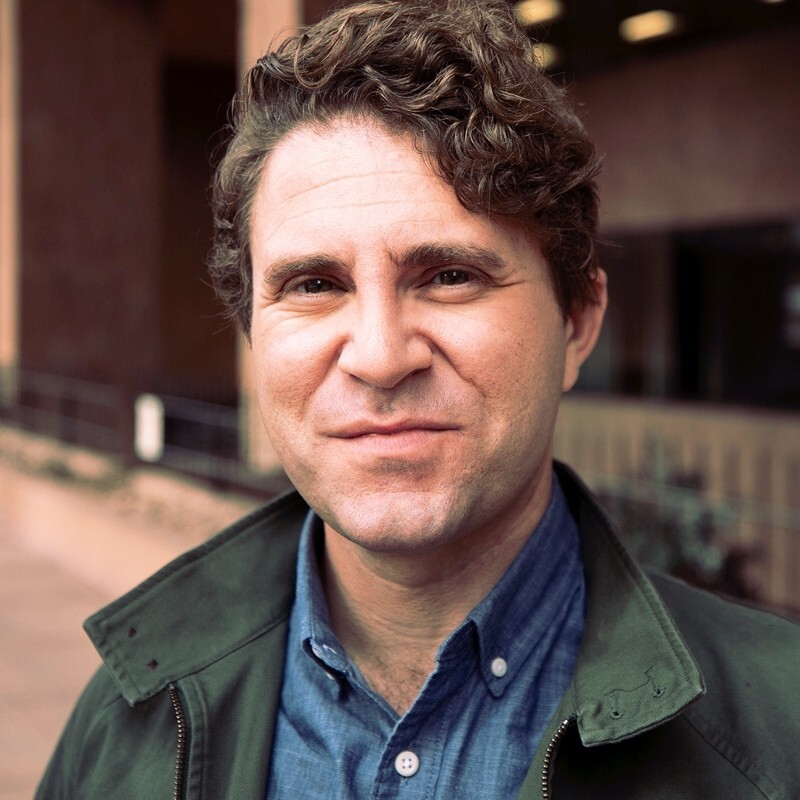

Zachary Mannheimer, Alquist’s founder and chairman, noted 3D concrete printing has only been around for about six years in the United States. He moved the company’s headquarters from Iowa to Greeley late last year, due to partnerships Alquist secured with the local Habitat for Humanity chapter, the city of Greeley and educational programs at nearby Aims Community College.

Advocates for the technology say 3D-printed homes are faster to build, stronger and more resistant to natural disasters like wildfires. Mannheimer also says once companies like his can build at scale, the final price of 3D-printed homes could be 20 to 30 percent less than traditional homes. At this point, Mannheimer’s team is working to keep the cost of his builds at parity with lumber houses.

“There's a lot more to learn than what we know currently,” Mannheimer said. “So every time we do it, we get better.”

Alquist’s initial contract at Hope Springs is for two duplex homes.

Construction on twelve lumber-built homes will begin on the site in July. Greeley-Weld Habitat for Humanity CEO Cheri Witt-Brown said she believes in the promise of 3D-printed homes but is looking for Alquist to prove it can deliver these initial homes on budget before expanding the contract for future years.

It’s also important the families who are receiving these 3D-printed homes are behind the technology themselves, she said.

“We’re not going to just say to Habitat families, ‘Hey, you've got to have that 3D printed home,’” Witt-Brown said. “There are things we have to navigate in the next few months before I can say yeah, we have a product that everybody wants.”

Once complete, Hope Springs will contain 174 Habitat for Humanity homes alongside 320 mixed-rate apartments. The community contains soccer fields and an on-site childcare center and it is within walking distance of grocery stores.

Witt-Brown said the mix of nonprofit, private and public sector partnerships employed for Hope Springs could be a model for other Colorado communities facing housing shortages.

“We're not going to solve the affordable housing crisis,” she said. “But we can certainly start to make movement with projects like this.”

Rachel Borum, a single mother and business manager for the campus library at the University of Northern Colorado, will receive the first duplex unit built by Alquist at Hope Springs.

Habitat homeowners purchase their homes at a discounted rate based on a monthly mortgage payment that is no more than 30 percent of their income.

The group paid about $400,000 to build the new home in Greeley including land fees. Witt-Brown said most families Habitat serves cannot afford a mortgage that costs more than $250,000. Habitat subsidizes the difference and carries a silent second mortgage for that amount for the life of the loan.